.

For what is a man profited, if he shall gain the whole world, and lose his own soul? Matthew 16:26

As many collectors within our community are already aware, a parasitic disease has been unleashed upon our hobby. It is an infection of greed and deceit and we, as a community, will not let this stand. All Engelhard has taken up arms in this fight against counterfeiting and we will remain vigilant in this battle against the corruptive forces within our community, knowing well its limits and complications.

As a community of collectors, we are all watching. And we are winning.

We must bear in mind that there are many more collectors than there are counterfeiters and sellers. Let this be a declaration of war against producers and sellers of counterfeits. Despite this lighthearted treatise, your involvement is known and we will resolve this matter in a method and timeline of our choosing. Our community continues to take action to educate members of our hobby and broadcast new counterfeit ingots as they come to market via the many precious metals forums. Of this, we can be proud. However, we are still in the early stages of our battle against corruption. All Engelhard vows to remain steadfast in our commitment of protecting the community by continuing to closely monitor and inventory counterfeit examples as they are observed. We are in discussion with the United States Patent and Trademark office as well as members of the BASF legal and marketing departments regarding this ongoing investigation.

It is important for us to also acknowledge that we are dealing with counterfeit ingots of decent reproduction quality. Many collectors have been deceived and there are others that choose to remain blind to the truth. We have heard reports from collectors that they have passed suspected counterfeit ingots around to different coin dealers, experienced collectors and established eBay sellers and no one suspected them as counterfeits. To an unsuspecting eye, the latest evolution of counterfeit ingots could be accepted as genuine. However, collectors must bear in mind that when requesting opinion of authenticity, the opinion must be that of a collector that has handled and studied hundreds of examples. Not just bought and sold. We mean, specifically, being intimately familiar with Engelhard examples of every weight class to include casting dimensions, detailed font study and strike characteristics. We would not be having any discussion if these counterfeits were not of accurate reproduction.

The scientific methods employed by our group to study and authenticate examples will remain closely held in order to protect the community, as it would be counter-productive to provide full and specific detail to the counterfeiters. We will, however, share enough information regarding our studies to confirm for the community that our methods are objective, accurate and conclusive. We are also able to provide a few quick and accurate litmus testing procedures for collectors to perform on their own.

Our group has completed six different methods of study on a sampling of counterfeit ingots and employed known genuine examples as our control group. The control group of genuine ingots came from an inventory of various collectors, and was assembled an extended period of time prior to counterfeit ingots coming to market in March, 2013. There is no question as to their authenticity. We have studied a genuine grouping of both 3oz and 5oz class ingots of same variety to ensure the most comprehensive and unbiased evaluation.

We will start with an introduction of our six scientific evaluation methods, then introduce our experiment group of ingots and proceed immediately to the results of each method. Our study will be concluded with presentation of a comprehensive summary analysis of ingot testing with results of each testing category for quick reference, in pass or fail grading. As part of our continual research, we are keeping living registries of genuine and suspected counterfeit ingots to include photos as well as web archives of former and current listings of suspicious ingots for community reference.

Scientific Evaluation Methods

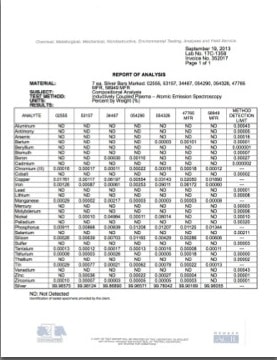

[Method 1] Analysis of compositional metal content: Evaluation method includes traditional drill-assay method of digesting samplings into an acid solution for full range ICP-AES instrumentation evaluation, or inductively coupled plasma atomic emission spectroscopy. This method ionizes Argon gas in an intense electromagnetic field. A stable, high temperature plasma of about 7000 K is generated as the result of the inelastic collisions created between the neutral argon atoms and the charged particles. A peristaltic pump delivers an aqueous sample into a nebulizer where it is changed into mist and introduced directly inside the plasma flame. Our sample immediately collides with the electrons and charged ions in the plasma and is itself broken down into charged ions. The various molecules break up into their respective atoms, which then lose electrons and recombine repeatedly in the plasma, giving off radiation at the characteristic wavelengths of the elements involved.

Within the optical chambers, after the light is separated into its different wavelengths, the separated colors fall upon an array of semiconductor photo-detectors. The intensities of these wavelengths are measured simultaneously, allowing the instrument to analyze every element to which the unit is sensitive all at once. The intensity of each line is then compared to previously measured intensities of known concentrations of the elements and their concentrations are then computed by interpolation along the calibration lines for final compositional determination.

[Method 2] Analysis of organic surface residues: Extraction of surface residue with an organic solvent for compositional characterization of surface elements, quantitative analysis by energy-dispersive spectroscopy [EDS] equipped scanning electron microscope [SEM]. The EDS method of evaluation uses the characteristic X-rays generated from a sampled bombarded with electrons to identify the elemental constituents comprising the sample. This technique generates a spectrum in which the peaks correspond to specific X-ray energy lines corresponding to specific elements that can then be identified. EDS is capable of qualitative and semi-qualitative chemical analysis of elements atomic numbers 6 through 94. The detected elements are normalized to total 100%. The nominal detection limit for most elements is 0.5%. Elements present in summary analysis include Silver, Carbon, Oxygen, Chlorine, Sulfur, Silicon, Aluminum, Magnesium and Sodium.

[Method 3] Analysis of ingot surface characteristics: Microscopic visual evaluation of ingot font, hallmark and surface characteristics under 60x magnification. Analysis of casting surface finish and induced toning.

[Method 4] Analysis of ingot dimension: Digital micrometer measurements completed of ingot height, width and depth from multiple control points, to include from diagonal corners of an ingot’s leading edge.

[Method 5] Analysis of ingot weight: Standard method of digital scaling in gram weight.

[Method 6] Analysis of statistical probability: This evaluation method is so easy, a caveman can do it. In the spirit of irony, All Engelhard was granted opportunity to exercise this method of evaluating two particular ingots only after completing all other testing methods outlined in our study. The collector community will agree this method renders the rest of our research redundant and confirms the existence of counterfeit ingots conclusive, beyond any level of doubt. We will save the best for last.

Introduction of the Players

Experimental Group | Counterfeit Examples:

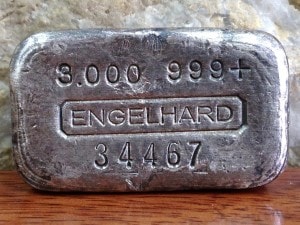

3oz Class | 34467 | Counterfeit Example: This ingot is the latest series of 3oz class counterfeit ingot.

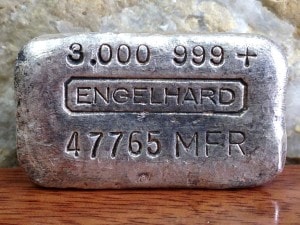

3oz Class | 47765 MFR | Counterfeit Example: This ingot is also the latest series of 3oz class ingot, in MFR variation.

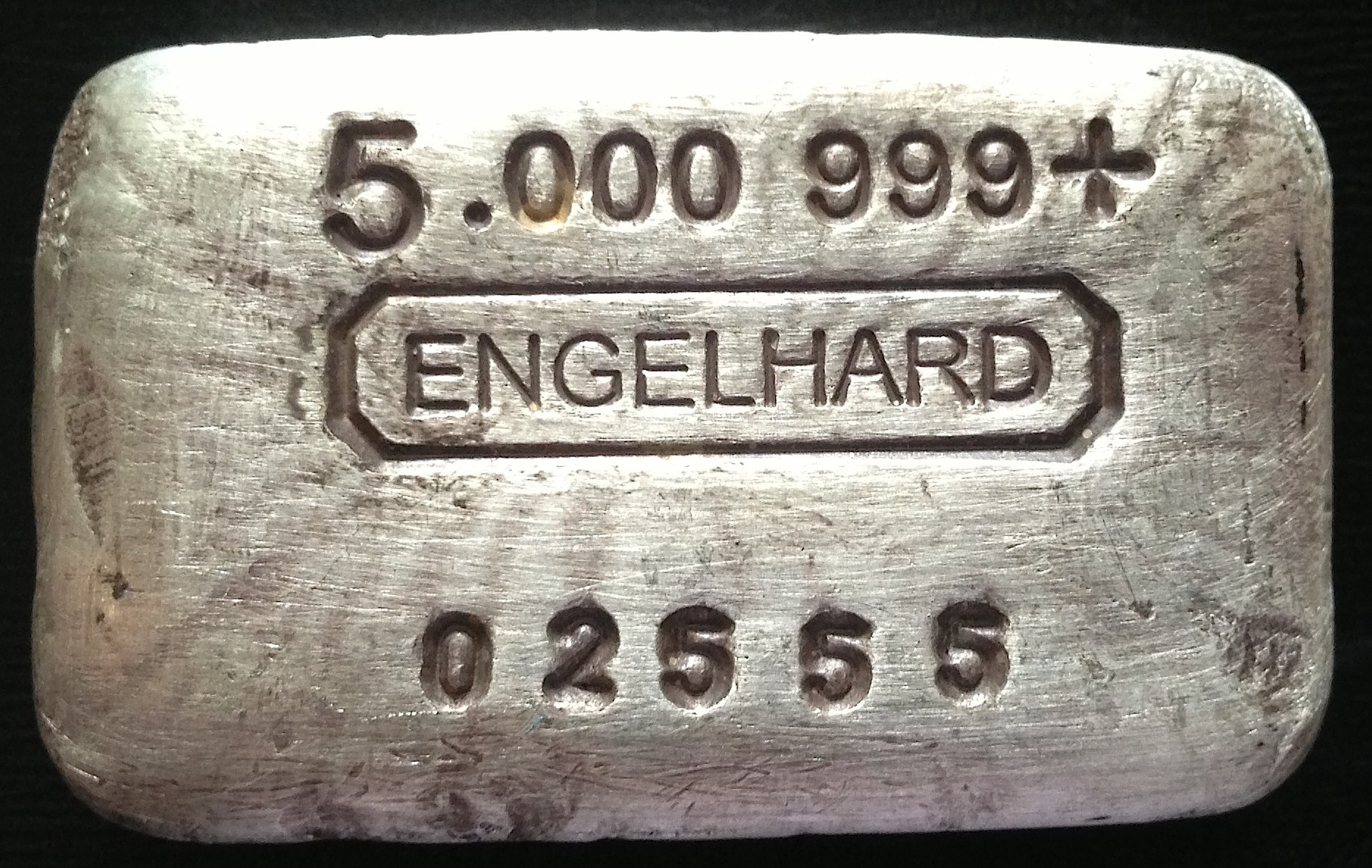

5oz Class | 02555 |Counterfeit Example: First series, crudely produced 5oz class ingot. Matches the first series variety of 5oz class ingot on our registry page, for which we have archived only one known auction seller.

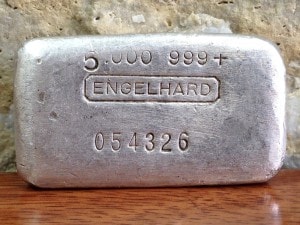

5oz Class | 054326 | Counterfeit Example: This is the latest, most evolved series of counterfeit 5oz class ingot and sourced from the same seller as the 02555 5oz ingot.

Control Group | Genuine Examples:

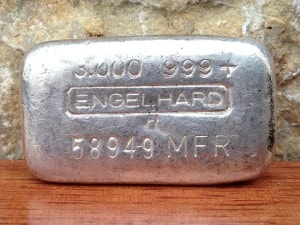

58949 MFR | Control Group | Genuine Example: This ingot served as our ICP-AES assay control example for both the 34467 and 47765 MFR counterfeit ingots.

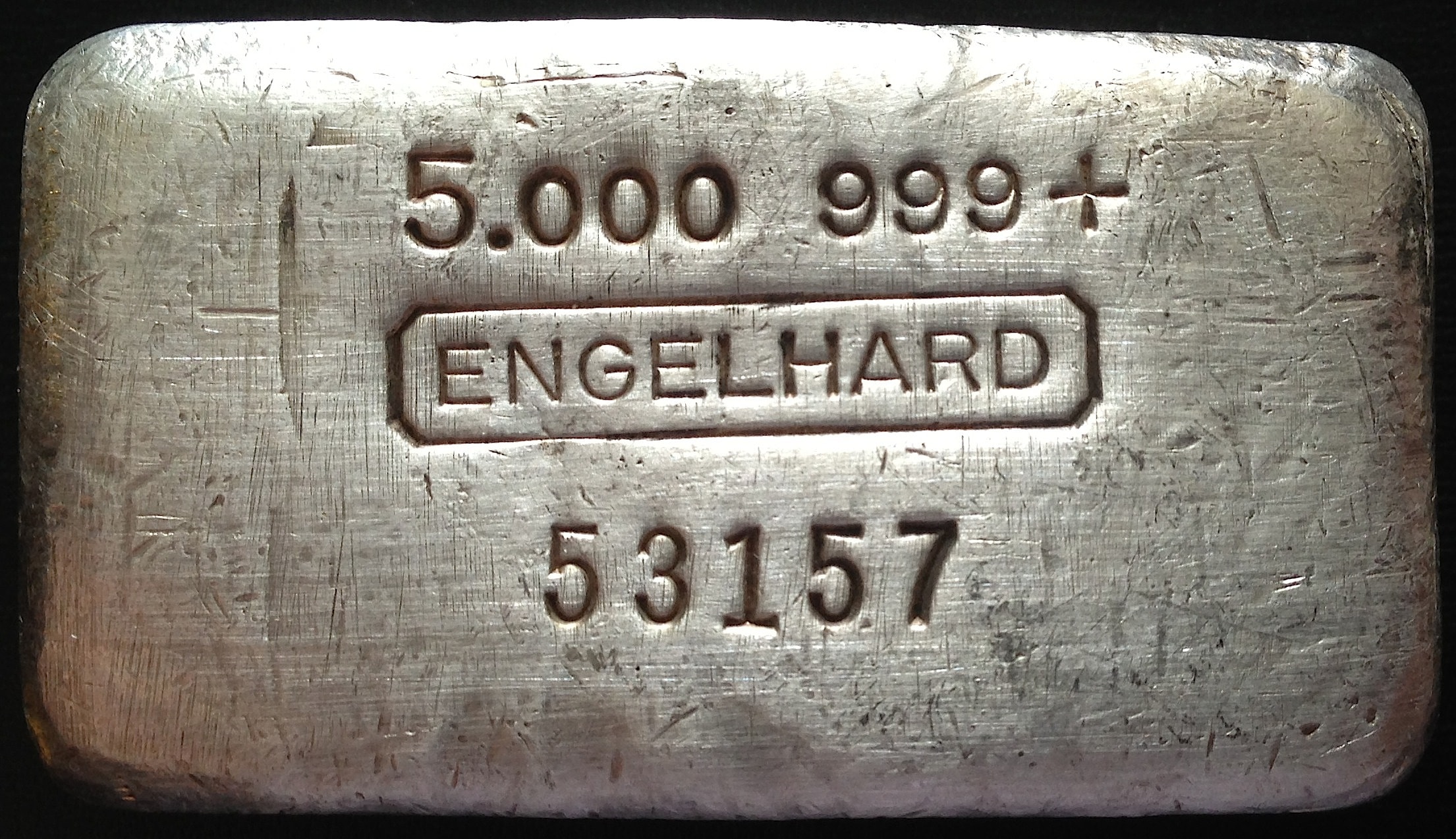

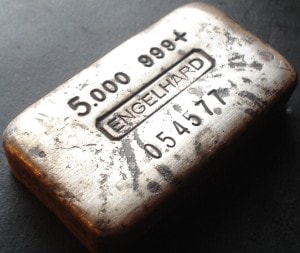

53157 | Control Group | Genuine Example: 5oz class ingot of same variety as the 054326 counterfeit example, control group for our 5oz ICP-AES assay evaluation.

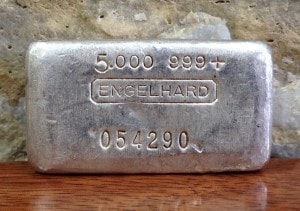

054290 | Control Group | Genuine Example: Second 5oz class ingot matching 054326 counterfeit variety, our secondary control for ICP-AES assay evaluation.

Experiment Results

[Method 1] Analysis of compositional metal content:

The ICP-AES assay results are so critical to our study that we must ensure they are interpreted objectively for their conclusiveness to be fully appreciated. Upon cursory review, they are simple to comprehend and may suggest negligible differences. However, this story has just begun. The anomalies observed in the counterfeit assay results are, in fact, so compelling, that it is incumbent upon us to first briefly reference the benchmark regarding silver purity.

ASTM International | Standard Specification for Refined Silver | B413

ASTM International, formerly American Society for Testing and Materials, was founded in 1898 and is an internationally recognized organization that establishes and publishes technical standards for various industries. It has remained the standard for all the world’s major precious metals refiners since its inception. While there have been numerous revisions regarding ASTM Standard, the fundamental requirements of silver purity have not changed. As such, we present Standard Specification B413-69, which is appropriate to reference given the production period our suspected counterfeit ingots suggest. Presented below are the applicable considerations from this designation.

1.1 This specification covers refined silver in cast bar form in three grades as follows:

1.1.1 Grade 99.90 | Silver having a minimum fineness of 999.0 commonly referred to as ‘commercial bar’ or ‘bullion.’

1.1.2 Grade 99.95 | Silver having a minimum fineness of 999.5.

1.1.3 Grade 99.99 | A premium grade having a minimum fineness of 999.9.

It is when viewed through this ASTM lens of reference that our results become truly consequential. An ingot either meets ASTM Standard Specification B413 or it does not. In relative terms, an individual either has a terminal illness, or does not. Here are our results:

3oz Class | 34467 | Counterfeit Example: 99.86890 – Failure of ASTM Standard.

3oz Class | 47765 MFR | Counterfeit Example: 99.90189 – Within ASTM Standard.

5oz Class | 02555 |Counterfeit Example: 99.96570 – Within ASTM Standard.

5oz Class | 054326 | Counterfeit Example: 99.78042 – Failure of ASTM Standard.

58949 MFR | Control Group | Genuine Example: 99.96055 – Within ASTM Standard.

053157 | Control Group | Genuine Example: 99.98124 – Within ASTM Standard.

054290 | Control Group | Genuine Example: 99.96571 – Within ASTM Standard.

Surprisingly, the least visually convincing counterfeit example, 5oz class 02555, demonstrated results that could pass for one of our control group. It is clear to us that the counterfeiters are using high quality silver, quite possibly melting common Engelhard examples for their pieces. However, two of the four experimental examples fail the assay evaluation. We believe this may be due to a contaminated smelting crucible or perhaps tainted stock material.

Photographic Documentation | Assay Completion

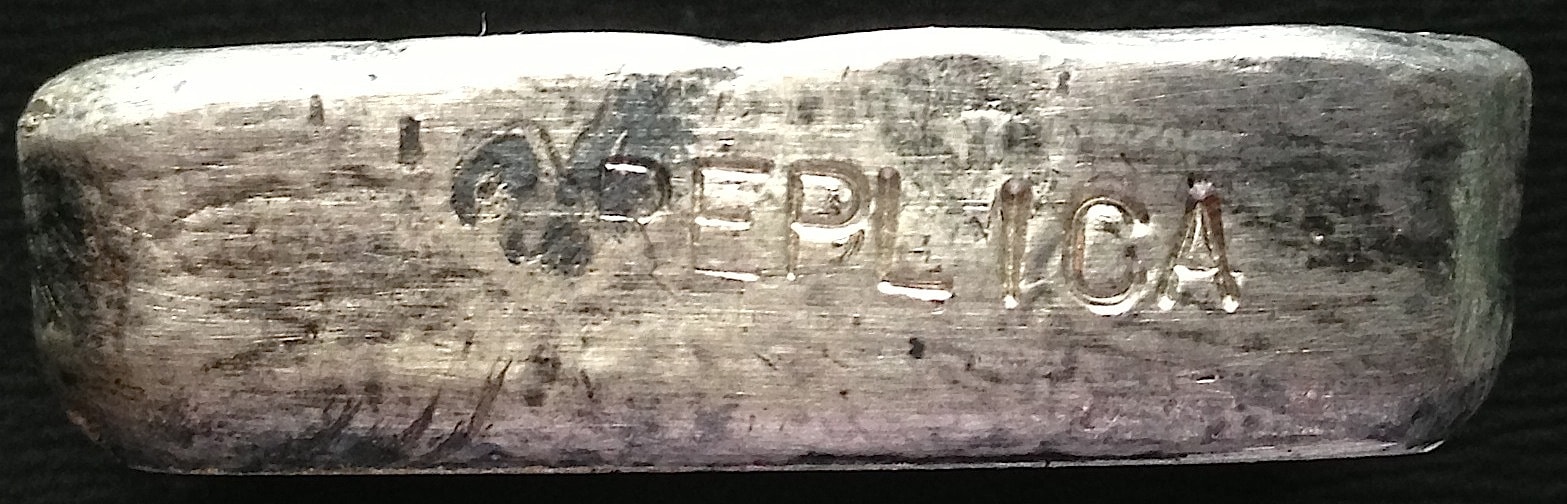

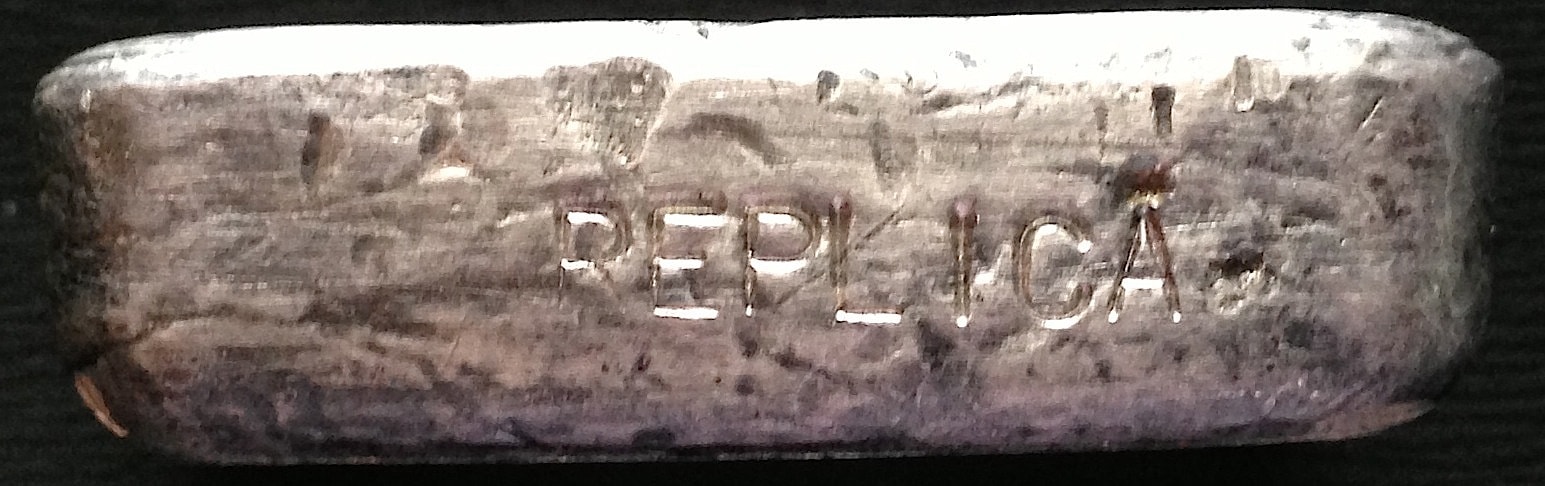

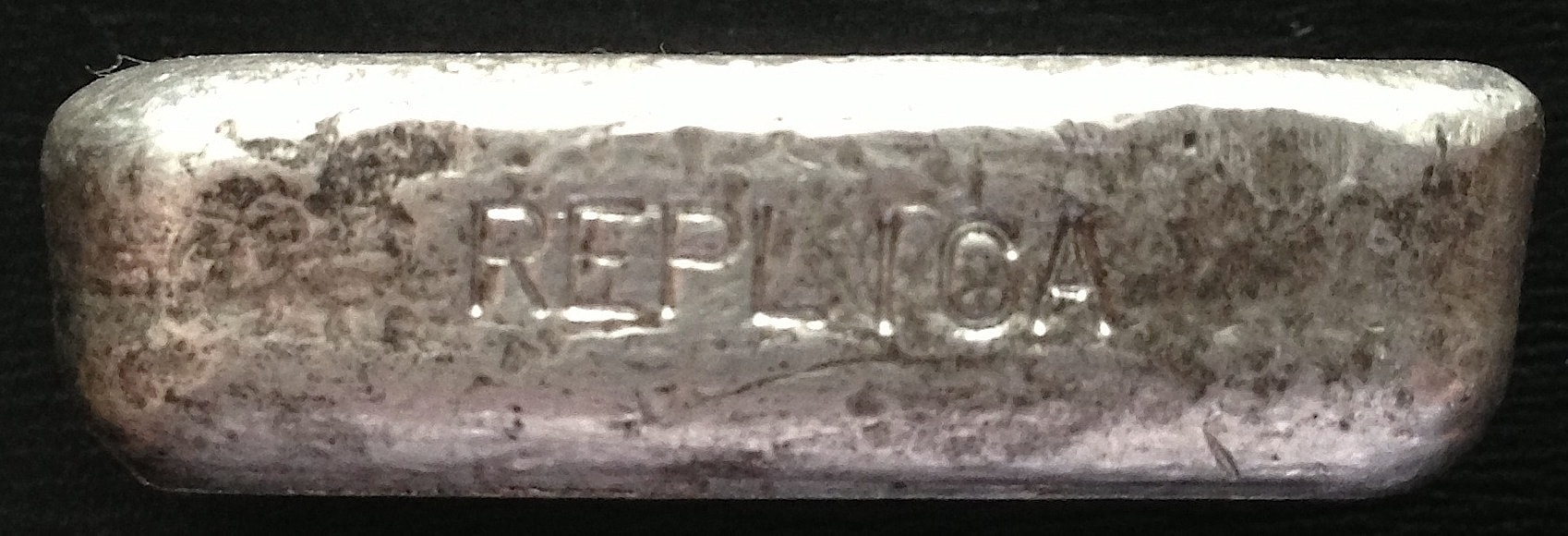

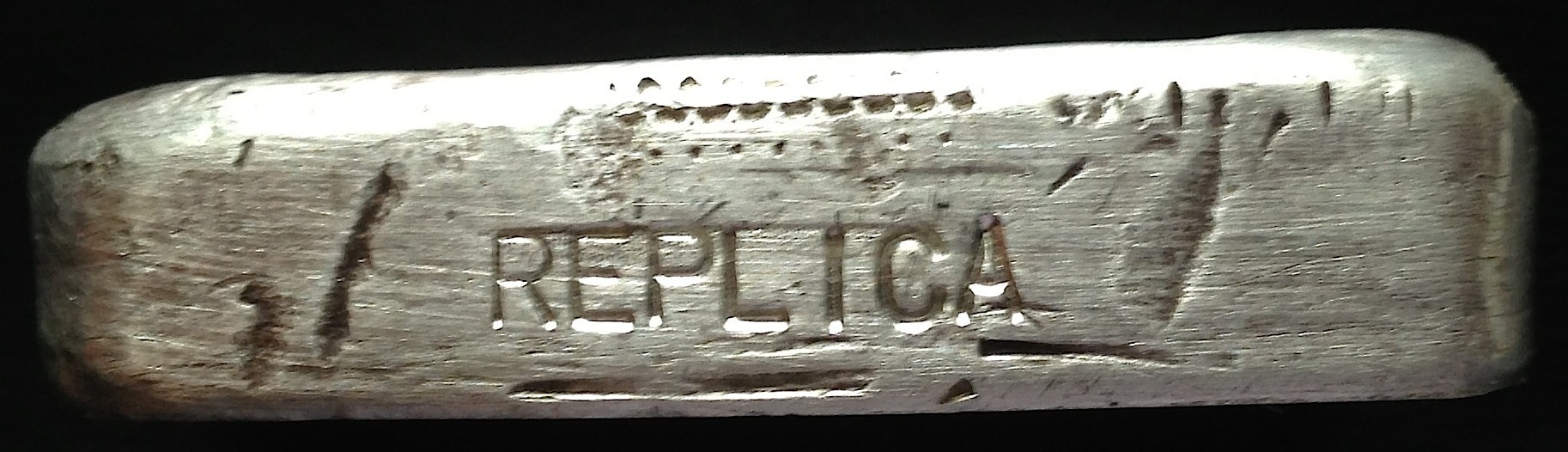

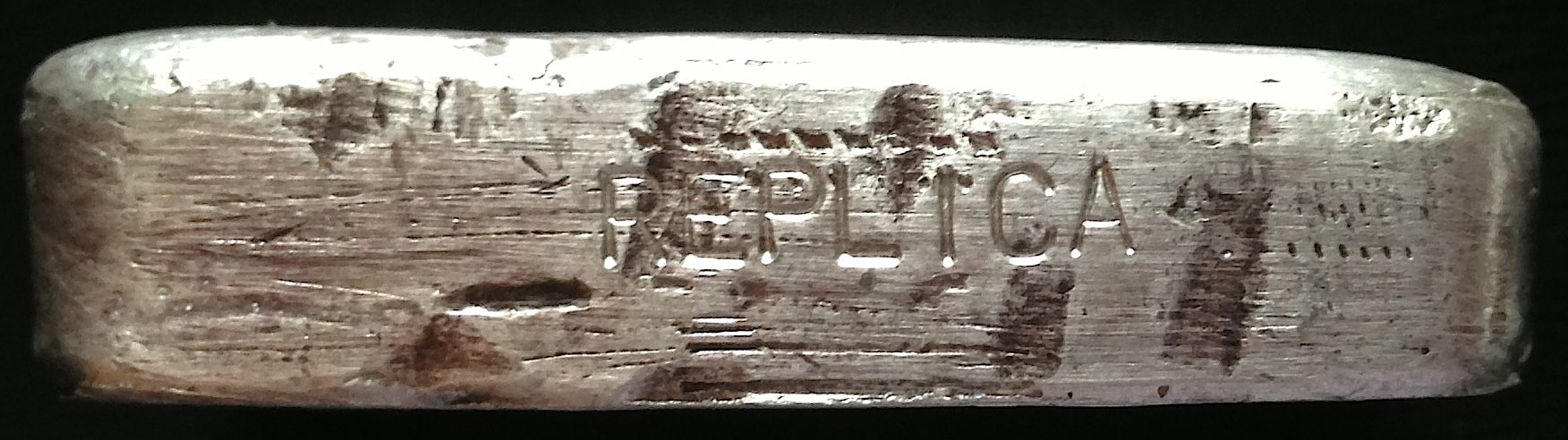

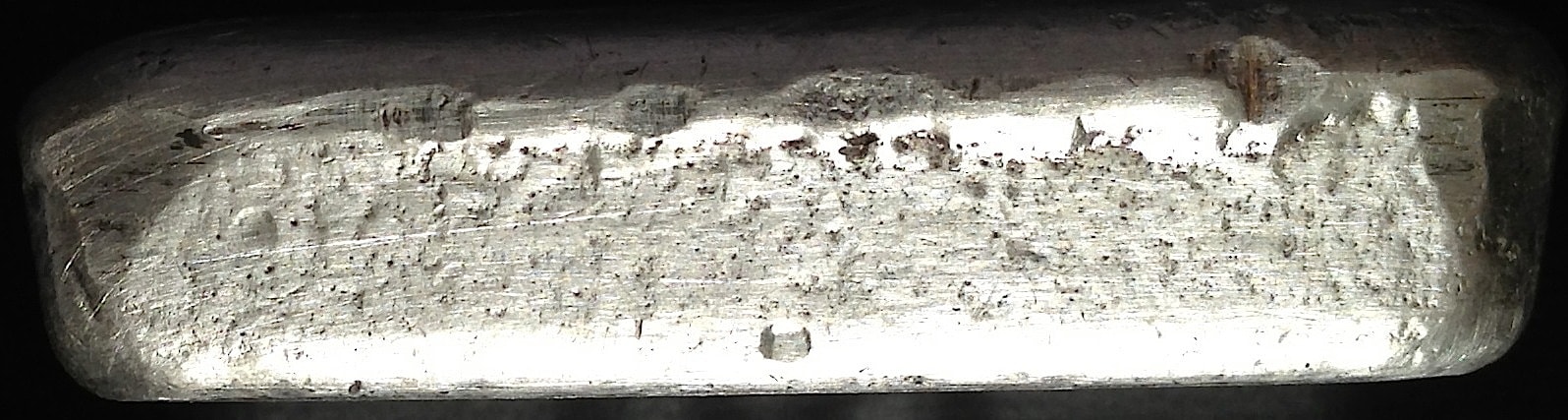

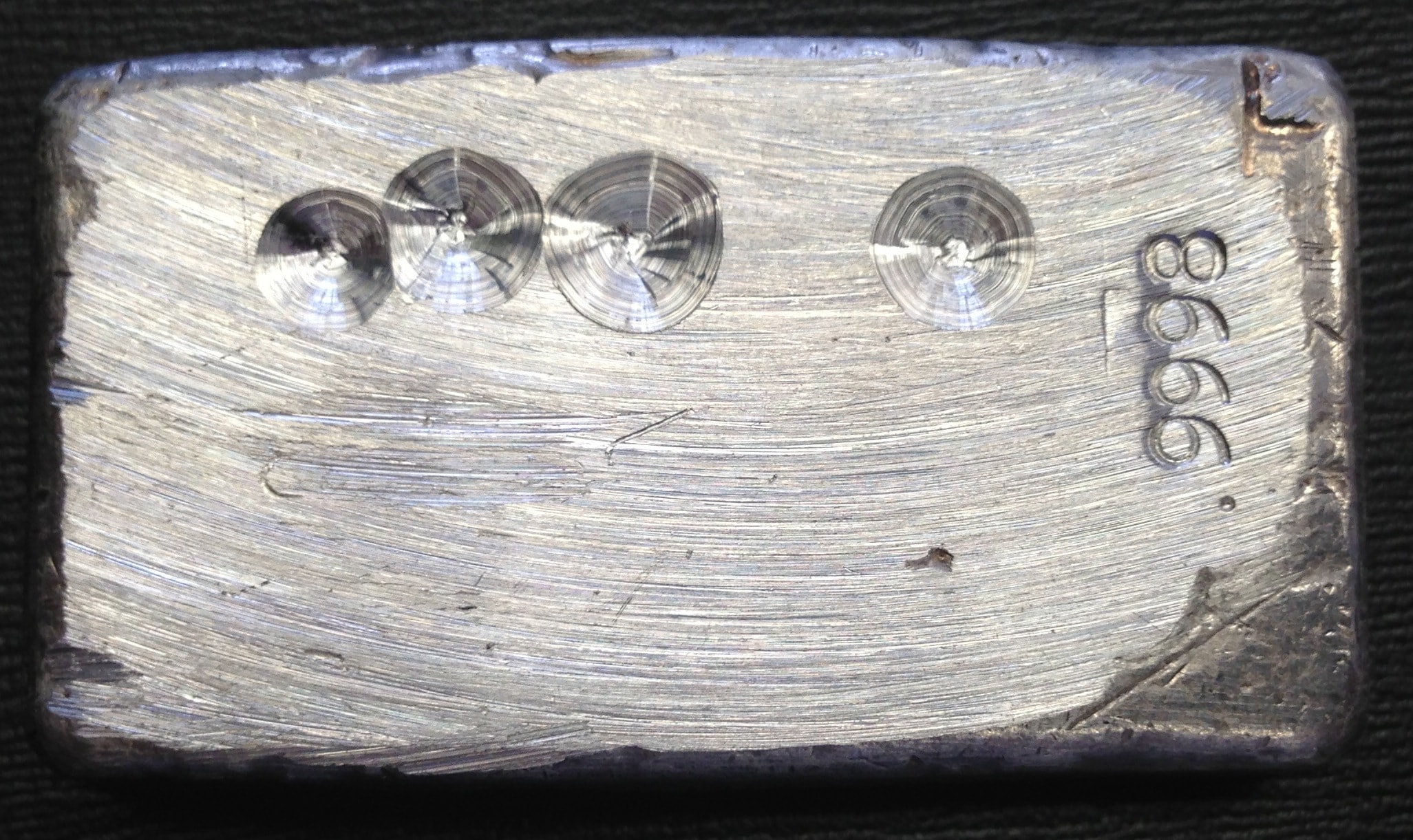

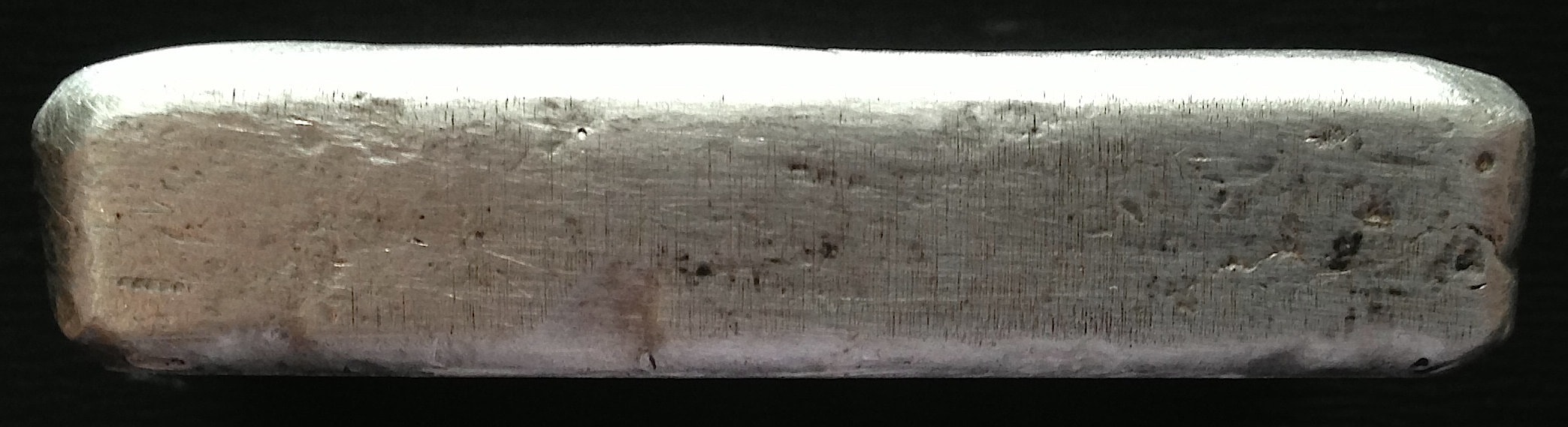

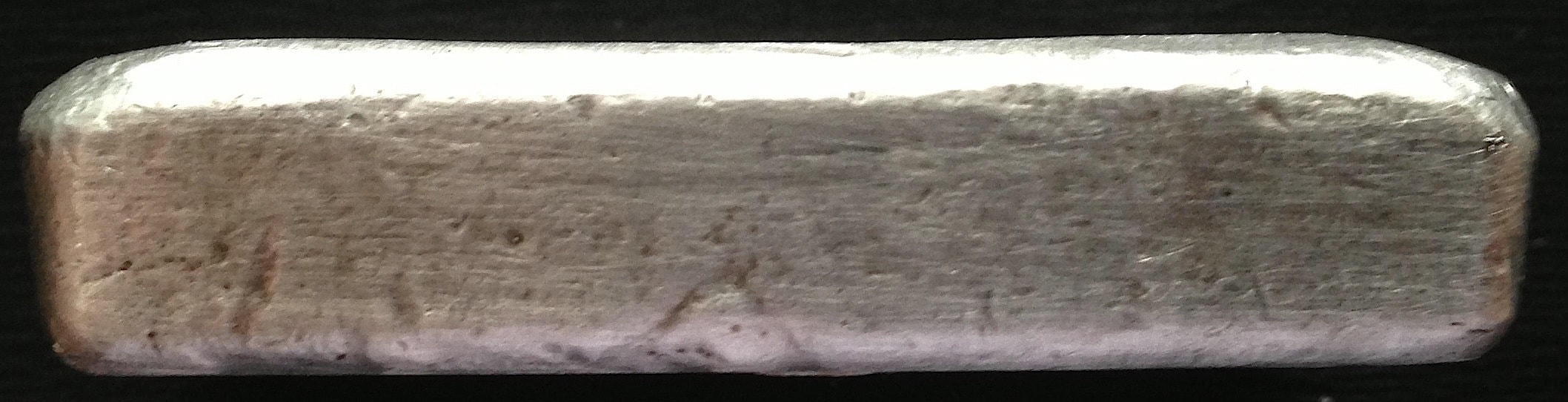

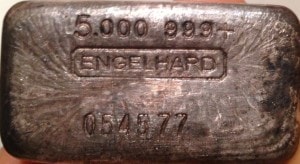

Several collectors have expressed interest in how both experiment groups of ingots appear after our full range of testing. We are including photographs of our experiment ingots for the community to review. The reverse of each ingot was ground down prior to drilling to ensure internal sample material was obtained for our assay. Upon conclusion of our experiment, each ingot was stamped with determined purity. Our counterfeit group of ingots were also stamped ‘REPLICA’ on the reverse and each leading edge.

Experimental Group | Counterfeit Examples:

Experimental Group | Genuine Examples:

[Method 2] Analysis of Organic Surface Residues:

3oz Class | 34467 | Counterfeit Example: Increased levels of sulfur surface residue – indicates induced toning by method of sulfur application.

3oz Class | 47765 MFR | Counterfeit Example: Increased levels of sulfur surface residue – indicates induced toning by method of sulfur application.

5oz Class | 02555 |Counterfeit Example: Increased levels of chlorine surface residue – indicates induced toning by method of chlorine application.

5oz Class | 054326 | Counterfeit Example: Increased levels of sulfur surface residue – indicates induced toning by method of sulfur application.

58949 MFR | Control Group | Genuine Example: Tested normal for surface residue.

053157 | Control Group | Genuine Example: Tested normal for surface residue.

054290 | Control Group | Genuine Example: Tested normal for surface residue.

[Method 3] Analysis of ingot surface characteristics:

We will lay the framework for results of this evaluation method with a brief dissertation on induced toning. Our EDS-SEM Results have already demonstrated induced toning by means of sulfur and chlorine application, and we now will speak specifically to the methods by which this was achieved. We believe it imperative for any advanced collector, if you have not already done so, to experiment with induced toning. This is an easy and insightful experiment that can provide a collector with the necessary knowledge needed to recognize possible induced toning on any example.

The experiment we present requires only three items [Lab coat optional]:

[1] Silver ingot or round of choice.

[2] Hard boiled egg.

[3] Ziplock bag.

Here are the results we observed with a 1984 Prospector and 1oz commercial bar, serial PW55970. These pieces were sulfur-exposed for 30 minutes and represent the extreme end of induced toning. We strongly encourage collectors to try this method of toning in order to arm themselves against sellers attempting to peddle examples that are ‘starting to rainbow.’

An ingot’s natural toning may be considered similar to a natural suntan. It happens naturally, it requires time and cannot be immediately applied. It is not sprayed or brushed on nor does not rub off or flake away from the recesses of an ingot’s font. This particular counterfeit example 47366 MFR, below, has had such an excessive amount of induced toning application that it has begun to flake out of the ingot’s lettering and hallmark border. We believe this toning was induced by method of sulfur paste application. We further observe a sanded obverse finish for weight calibration, not seen on genuine 3oz class of any variety. We conclude with commentary on the ingot’s leading edge, side and reverse – specifically the contradictory presence of extreme black splotchiness of induced tone against the backdrop of the ingot’s natural, frosted patina.

The remainder of this evaluation method is dedicated to our study of ingot surface characteristics. We have studied multiple counterfeit ingots under 60x magnification and the results are conclusive. Counterfeit ingots demonstrate significant anomalies in casting surface finish and font detail. Our evaluation results are limited to one font anomaly as a matter of protection for our community. However, we can report that multiple points of similar irregularity were observed on every ingot and provide a road-map for further revealing counterfeit ingots upon magnified evaluation.

We now present the letter N under 60x magnification for further discussion, taken from our 5oz class counterfeit ingot 054326 and genuine examples 054246 and 054290. These pictures allow us to speak to several points of interest regarding the counterfeit example, specifically:

[1] Obverse Sanding Method: Many collectors are already aware that this particular general variety of 5oz class piece will demonstrate a sanded obverse finish, which Engelhard performed in order to allow proper weight calibration. The first detail we will draw attention to is that the sanding on counterfeit ingot 054326 runs horizontally, opposite of the two genuine examples that demonstrate the customary vertical sanding method.

[2] Induced Toning Hues: We again emphasize that natural ingot toning can be described as a suntan in that it provides a golden, natural surface shading. Genuine examples 054246 and 054290 illustrate a golden hue within the recesses of the font strike, while counterfeit example 054326 only offers a the grayish-black hue that results from induced toning application.

[3] Font Die Characteristics: This observation is perhaps the most interesting and incriminatory of the counterfeit ingot. The font and hallmark dies used by Engelhard were hand-cut dies and not CNC machined as many modern refiners employ for weight, purity, serial number and hallmark application. Hand-cut dies will always demonstrate unique, identifiable character under magnified study vs. the precision CNC machined dies used on the counterfeit examples. If we draw our attention to the upward right leg of the N, toward the top of the strike, we observe on both genuine examples an ‘endearing quirk’ of the Engelhard hand-cut die. This convex bubble area is impossible to reproduce on a CNC produced die. This type of font anomaly is observed on multiple other points of surface study on the counterfeit ingot and lends further conclusive evidence to our study.

[Method 4] Analysis of ingot dimension:

A control group of 10 genuine examples of both 3oz and 5oz weight class were included for this evaluation method. Micrometer measurements were recorded from across each genuine ingot’s width, depth and height in order to establish control limits. The diagonal distance from each ingot’s leading edges were also measured for specific cross-dimension, referred to as cross-point dimension. For our experiment, we recorded the widest of both diagonal cross-point measurements on all ingots and subjected both 5oz class ingots to the same control limits as they seem intended to match variety. Here are our results:

| 3oz Class | 34467 | 3oz Class | 47765 MFR | 5oz Class | 02555 | 5oz Class | 054326 | |

| Ingot Width: | 39.22mm | 39.76mm | 52.89mm | 48.02mm |

| Control Limit: | 39.04mm – 40.21mm | 39.40 – 40.26mm | 51.37mm – 52.93mm | 51.37mm – 52.93mm |

| Ingot Height: | 23.30mm | 22.96mm | 30.04mm | 29.64mm |

| Control Limit: | 22.40mm – 23.11mm | 21.98mm – 23.97mm | 27.72mm – 30.01mm | 27.72mm – 30.01mm |

| Ingot Depth: | 11.68mm | 11.79mm | 11.17mm | 12.02mm |

| Control Limit: | 11.18mm – 12.49mm | 11.23mm – 12.04mm | 11.16mm – 12.02mm | 11.16mm – 12.02mm |

| Ingot Cross-Point: | 41.58mm | 41.45mm | 56.78mm | 52.29mm |

| Control Limit: | 42.41mm – 43.80mm | 42.49mm – 43.68mm | 55.51mm – 57.37mm | 55.51mm – 57.37mm |

In the spirit of consideration, we are granting a pass to all counterfeit ingots in conclusion of Method 4 analysis. While some ingot dimensions landed outside of our control limits, we feel that they are accurate enough overall to constitute a pass. Poured ingots will all vary slightly in some dimension as it is the nature of an old-pour piece. Additionally, this is a relatively simple anomaly to correct in casting method. However, All Engelhard has recorded a significant giveaway regarding counterfeit ingot geometry that will not be disclosed in this study. It is consistent on all counterfeit ingots observed under study, across all weight class.

[Method 5] Analysis of ingot weight:

A control group of 10 genuine examples of both 3oz and 5oz weight class were included for this evaluation method. Digital scale readings in gram weight measurement were recorded of each genuine ingot in order to establish control limits. Here are our results:

| 3oz Class | 34467 | 3oz Class | 47765 MFR | 5oz Class | 02555 | 5oz Class | 054326 | |

| Ingot Weight: | 93.65g | 93.80g | 155.60g | 155.64g |

| Control Limit: | 94.20g – 95.10g | 94.43g – 94.70g | 155.41g – 156.50g | 155.40g – 156.53g |

Although the ingot weight results are not conclusive for all counterfeit examples, it is again incumbent upon us to bring attention to a common detail observed on these counterfeit ingots. Below, a photo of our counterfeit 5oz class 054326 is presented to demonstrate how the counterfeiters accomplish proper weight calibration by grinding the corners. This observation provides clarity as to how half of our experiment group ingots pass our weight evaluation, albeit the most simple attribute to get correct on a counterfeit piece.

[Method 6] Analysis of Statistical Probability:

Two noticeably different 5oz class ingots of matching variety with identical serial number, traced to the same individual. All Engelhard has been tracking serial numbers of fake and genuine examples for some time, as two ingots of matching serial number would be our smoking gun. We assume serial numbers used on counterfeit examples are of ingots stored away in a collection known or kept by counterfeiters and not slated for sale. This, however, does not preclude them from using the same serial number on two of their own counterfeits, as we see here. You don’t need a lab coat and beakers for this one, folks… presented with no further comment, beyond that of our caveman.

|

Experiment Summary Chart

| Method 1 | Assay | Method 2 | Residue | Method 3 | Surface | Method 4 | Dimension | Method 5 | Weight | Method 6 | Probability | |

| 3oz | 34467 | Fail | Fail | Fail | Pass | Fail | Pass – At This Time |

| 3oz | 47765 MFR | Pass | Fail | Fail | Pass | Fail | Pass – At This Time |

| 5oz | 02555 | Pass | Fail | Fail | Pass | Pass | Pass – At This Time |

| 5oz | 054326 | Fail | Fail | Fail | Pass | Pass | Fail |

Executive Summary and Conclusion

We conclude this study in full faith that our dissertation brings clarity and the beginning of closure to this issue of counterfeit Engelhard ingots. Many collectors have had a long, hard road in trying to convince other collectors these pieces existed, only to be mocked or told it is impossible, when they knew in their heart that a piece was just ‘not right.’ Unfortunately, it is the current reality of our collector world to have been contaminated by these counterfeit pieces.

Our exposition has demonstrated beyond any level of doubt, by means of traditional drill assay and multiple ancillary scientific methods, the existence of these counterfeit ingots. As such, this is a call to arms for our community.

We must remain continuously vigilant against these traitors of our hobby. We must continue to educate our community, especially new collectors, so that we are united and prepared to recognize and inventory counterfeit pieces as they are observed. We collectors will ensure those responsible for this treason are held accountable for their actions. We will not tire, we will not falter, and we will not fail.

To that end, All Engelhard stands ready.